Everything You Need to Know About HYCO Wireless Light Tag and Pick-to-Light Solutions

In today’s fast-paced pharmaceutical, e-commerce, and supply chain industry, efficiency and accuracy are critical to success. Among the innovative tools designed to optimize operations is the Wireless Light Tag—a game-changing technology revolutionizing inventory management and order fulfillment. Often referred to as a Wireless Pick-to-Light Solution, this system helps businesses achieve unparalleled accuracy and efficiency. But what exactly is a Wireless Light Tag, and how does it work? Let’s dive in.

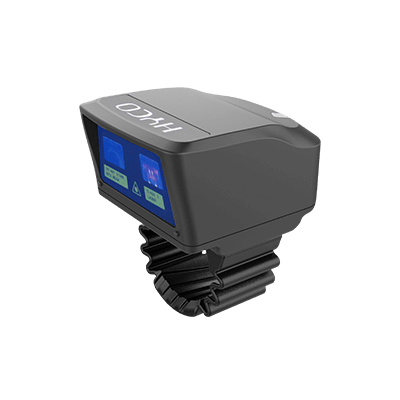

What is HYCO Wireless Light Tag?

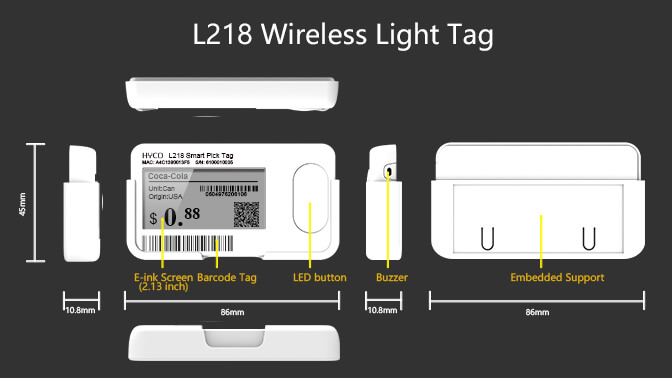

HYCO Wireless Light Tag is a compact, battery-powered system that integrates advanced wireless communication and LED light guidance technology. Designed to enhance inventory and warehouse operations, these tags attach to storage bins, racks, or individual items to provide real-time visual cues. This technology enables workers to quickly and accurately locate, pick, and manage inventory, streamlining workflows and reducing errors.

Key Features of Wireless Light Tags

Wireless Light Tags come equipped with features that make them essential in modern warehouses and distribution centers:

* Real-Time Visual Guidance

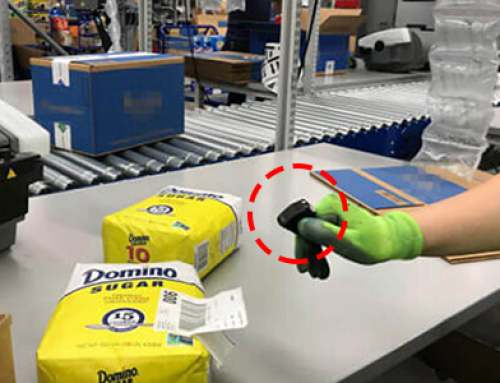

Using LED lights, these devices direct workers to the exact location of items, minimizing search time and errors. This feature is especially valuable for high-volume picking operations and inventory replenishment.

*Wireless Communication

Wireless Light Tags connect seamlessly with warehouse management systems (WMS) via wireless protocols, ensuring accurate and up-to-date inventory tracking.

*Energy Efficiency

Powered by ultra-low-power technology, Wireless Light Tags offer extended battery life and rechargeable, reducing operational costs and contributing to environmental sustainability.

*Ease of Reuse

When inventory is depleted, the system automatically unbinds the tag and prompts workers to retrieve it for reuse, promoting cost efficiency and sustainability.

How Wireless Light Tags Improve Warehouse Operations

Wireless Light Tags go beyond basic tools—they are transformative for several key areas:

Enhanced Picking Accuracy

By visually guiding workers to the correct items, Wireless Light Tags significantly reduce picking errors and improve order fulfillment accuracy.

Faster Inventory Turnover

LED light signals in Wireless Light Tags help prioritize items nearing expiration, optimizing stock rotation and minimizing waste. This feature is crucial for industries like retail and pharmaceuticals.

Seamless Integration

Wireless Light Tags are compatible with most WMS platforms, offering a scalable solution for businesses looking to improve operational efficiency.

Ergonomic Benefits

Eliminating reliance on handheld devices or paper-based systems, Wireless Light Tags simplify workflows and reduce physical strain on workers.

Applications of Wireless Light Tags

Wireless Light Tags are highly versatile and suitable for various industries:

Retail: Enhance shelf stocking and streamline inventory management in retail stores or fulfillment centers.

Manufacturing: Improve assembly line efficiency by guiding workers to the right components at the right time.

Pharmaceuticals: Track and prioritize expiration-sensitive items for accurate and timely deliveries.

E-commerce: Speed up picking and packing processes, ensuring fast and accurate order fulfillment.

Why Choose HYCO Wireless Light Tag Solution?

HYCO Wireless Light Tag Solution is a state-of-the-art system that combines innovative design, industry expertise, and the proprietary ULPCP (Unique Ultra-Low Power Consumption Platform). Built with advanced technology and seamless integration, our solution is crafted to help businesses achieve unmatched efficiency, accuracy, and sustainability in their operations. Whether you're managing a high-volume warehouse or looking to reduce waste, HYCO Wireless Light Tags are the ideal choice for modern supply chain operations.

The Wireless Light Tag is a must-have technology for businesses aiming to stay competitive in the fast-evolving pharmaceutical, e-commerce, and supply chain industry. By adopting this innovative solution, companies can enhance operational efficiency, minimize errors, and achieve a sustainable approach to inventory management.