The fourth generation of barcode technology will usher in the next wave of productivity in logistics. It will feature wearable scanning devices integrated with artificial intelligence (AI) that should bring about greater logistics efficiency.

It goes without saying that the invention of the barcode is one of the most crucial developments in the history of logistics and supply chain technology. The creation of barcodes solved the challenge of capturing data quickly and accurately at the same time, resulting in greater accountability in process management. Since the invention of the barcode in 1948, various formats of both linear and two-dimensional (often referred to as Quick Response or QR) symbols have emerged.

Today many industries such as logistics, retail, manufacturing, and pharmaceuticals rely heavily on barcodes for their management systems to handle the vast flow of goods, information, and finance. That’s because the invention of the barcode makes that possible.

Three Previous Generations of Barcode Technology

Barcode reading devices have already passed through three generations. The first generation featured bulky, fixed devices with high power consumption and slow speed. The second generation saw the introduction of handheld scanner, which became milestones in the miniaturization and practical use of scanning devices.

Handheld scanner benefited greatly from the widespread adoption of the Wintel computer system, a partnership between Microsoft Windows and Intel using Intel x86-compatible processors to run the Microsoft Windows operating system (OS). The Wintel computer system was commonly deployed in the retail and service industries and used in the supply chain areas of manufacturing and logistics.

The third generation witnessed the advent of handheld personal digital assistants (PDAs), which combined traditional scanner, computers, and wired networks into a single mobile information device. Those tools featured integrated miniature scanning engine, mobile computing, and wireless communication.

This evolution freed information technology from spatial limitations. Those devices were initially based on Microsoft's WinCE OS. Because Microsoft discontinued that OS a decade ago, PDAs now predominantly run on the Android platform despite that system’s inherent issues of high-power consumption, high hardware costs, and maintenance expenses.

Here Comes Generation Four

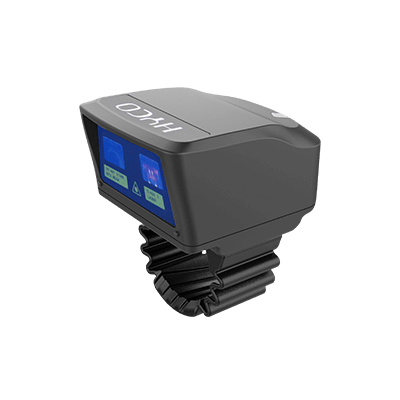

Since 1997, the scanning device industry has pursued wearable technology as the ultimate solution with the goal of freeing up the user’s hands from having to scan the barcode. The main forms of current wearable scanning products include ring scanner, glove scanner, watch scanner, and eyeglass scanner.

Wearable scanning technology has finally evolved where it can play a vital role in logistics. Ultra-low power consumption and user-friendly ring scanner represent the future of these types of these devices.

The development of ring scanner is expected to trend toward:

• lighter weight

• smaller size

• more comfort

• lower power consumption

• multi-parameter sensing

• multiple alert types

• longer wireless range

In the era of AI, key technologies influencing the efficiency and enhanced safety of logistics operations include:

• cloud-based algorithms

• industry-specific models

• high-speed wireless communications

• cloud-connected PDAs

• cloud terminal devices

• hands-free wearable Internet of Thing (IoT) devices

The most practical of these devices for use in logistics will likely be ring scanner and wearable computer.

Another type of four-generation bar code technology that should see greater use in logistics are IoT devices, such as ultra-low-power Wireless Light Tag. These will be used to help delivery drivers identify a specific package for selection out of the back of a van.

Another essential type of data capture technology will be advanced sensors that automatically collect comprehensive data from all areas of the supply chain and in such industries as manufacturing, retail, and logistics. Without access to this vast mine of data, AI will not have the necessary information it needs to undertake analysis and make decisions.

Wearable Devices Needed For Logistics in the AI Era

AI technology is expected to surpass human mental capabilities in computation, memory, and logical analysis. Although technology will be used as a substitute for the human mind in some areas, that’s not the case when it comes to technology substituting for human prehensility. Robotic technology is likely ten years away from replacing the function of the hand. The hand’s unique ability to sense temperature, pressure, and tactility makes it a highly functional executor for a variety of tasks.

Given then that logistics workers will still be required to use their hands to perform their duties, wearable scanning devices will ensure high levels of productivity when using barcodes to capture supply chain information.