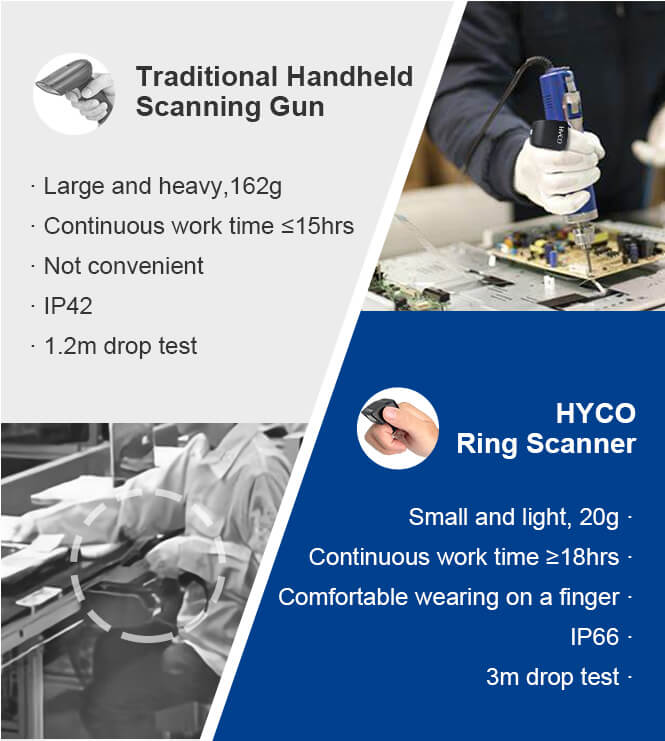

Efficient and high-quality production is essential in the manufacturing industry, and monitoring the entire production process is critical to ensure total quality. However, the traditional scanning guns and PDAs used in monitoring can hinder user movements and speed, affecting efficiency. This raises a potential conflict between the production department, which needs to maintain efficiency, and the QC department, which needs to monitor the process to ensure quality. This conflict can be addressed by finding a balance between efficiency and quality monitoring, for example, using HYCO’s wearable scanning technologies that do not hinder user movements and speed. Innovation technology empower labors safer easier and efficient work.

Improving Manufacturing and Tracing Efficiency

HYCO provides comfortable-wearing and low-power-consuming ring scanners. Unlike traditional scanners, ring scanners can be scanned in any situation without affecting the operation steps since they are wireless and do not require the user to hold the scanner. As a result, they perfectly balance quality monitoring and production efficiency, meeting the demands for high-speed real-time data collection throughout the production process.

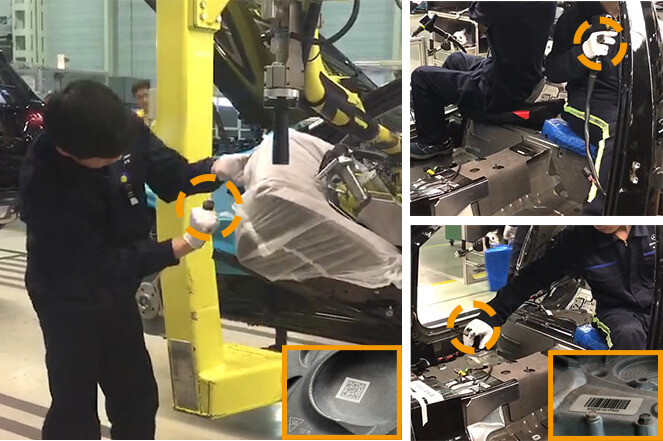

The ring scanner at home appliance assembly line

Innovative Pratical Scanner

Compared to traditional scanners, the HYCO Ring Scanner meets all six core indicators of practicality, making it a highly reliable and practical scanner product. With its solid construction and mass production capability, the ring scanner significantly improves efficiency while freeing up hands.

There is no need to re-plan the production line before using the ring scanner in the assembly line of the high-end manufacturing industry. In addition, ring scanners can also overcome issues encountered when scanning barcodes on internal or special-shaped parts in small spaces or when the barcode position is difficult to scan using traditional scanners. The ring scanner's design allows it to scan barcodes from different angles, making it a versatile tool for quality monitoring and production efficiency.

*The six core indicators of ring scanner practicality: weight less than 20g, comfortable wearing without physical discomfort, stable and reliable communication, continuous work time more than 18 hours, 3-meter drop test, IP66+ level.

Major Cases

The HYCO Ring Scanner has been utilized on multiple assembly lines of Samsung, Mercedes-Benz, Flextronics, GREE, and Haier, proving its effectiveness in enhancing production efficiency while maintaining total quality. Innovation technology empower labors safer easier and efficient work.