When it comes to consumer electronics products, we expect them nowadays to be lightweight and easy to use thanks to the engineering design. So why don't we have that same expectation for industrial electronic products (eg: Ring Scanner)?

Unfortunately, many people still believe that heavier and bulkier products are better suited to the workplace because they're considered to be durable and reliable. They hold onto that opinion despite the fact that company policies are increasingly focused on making the work environment better for employee safety and comfort.

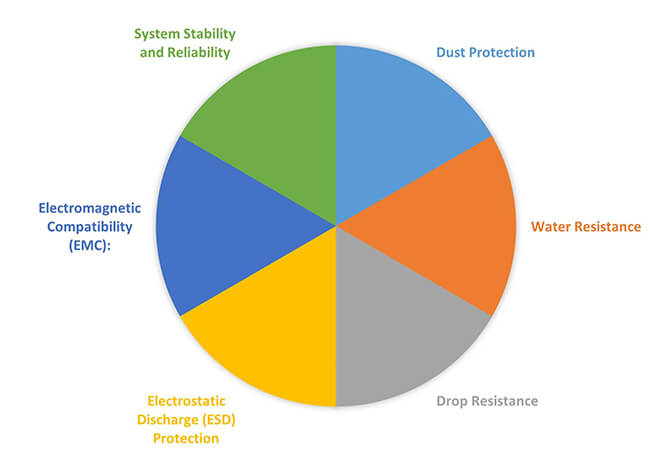

Six Criteria For Rugged Industrial Electronics

Industrial grade products that workers use as portable and wearable electronics don't have to be clunky and cumbersome. When it comes to the design and manufacture of those kinds of products, there are six key requirements for ruggedness.

1.Dust Protection:

Accumulated dust can trap heat and damage an electrical product. For optical electronics, in particular, the presence of dust inside the casing can lead to performance degradation or even functional failure.

2.Water Resistance:

A product has to be able to resist water exposure, whether through washing or immersion. The IP rating system ranks an industrial product's ability to withstand penetration by dust and water. The first digit in the “IPxx” rating represents the dust protection level, and the second digit represents the water resistance level. Common ratings include IP54, IP66, IP67, and IP68. The higher the numbers, the better the protection. For example, IP67 indicates the highest dust protection and the ability to withstand immersion in 1 meter of water for 30 minutes without water ingress.

3.Drop Resistance:

This measure typically specifies the height (in meters or feet) from which the product can be dropped onto a standard concrete surface without damage. The standard test involves dropping the product twice on its six faces, eight corners, and twelve edges. The height from which the product remains undamaged defines its drop resistance rating. For example, a product rated for a 3-meter drop has much stronger drop resistance than one rated for 1.8 meters, and a 1.8-meter drop rating is much stronger than a 1.2-meter rating.

4.Electrostatic Discharge (ESD) Protection:

People always carry static electricity. In cold and dry environments, static discharge can reach up to 30 Kilovolts (kV), which is why many automotive products require ESD protection up to 30KV. Internationally recognized ESD protection standards (air discharge model) are 4KV for consumer electronics, 15KV for industrial electronics, and 30KV for automotive electronics. Products must withstand the specified ESD discharge without damage or loss of functionality.

5.Electromagnetic Compatibility (EMC):

Any electronic product should prevent causing interference with other devices. Likewise, the product should also have strong immunity to withstand interference.

6.System Stability and Reliability:

It's essential that any portable and wearable electronic tools with communication functions maintain a stable connection. For example, Bluetooth peripheral devices need to maintain a connection without dropping or crashing, even in environments with heavy interference from Wi-Fi routers, high-power motors, or other equipment. While consumer products may tolerate lower standards (such as restarting after a crash or disconnection), industrial tools can't be subject to any kind of interruptions that severely impact work productivity or even safety.

Ease of Use Just As Important As Ruggedness

As you can see, industrial grade standards for portable and wearable tool electronics are entirely independent of the product's size and weight. When the technical differences between products are small, the size of the battery and printed circuit board (PCB) are generally similar.

The look of a heavier product stems from case thickness and the internal spacing between components that result in varying levels of dust, water, static, and drop protection. Even though a smaller-size product has similar functionality, power consumption, and PCB size to a larger one, heavier and bulkier products often have higher industrial grades.

Keep in mind that larger size and weight do significantly affect user experience. Therefore it's critical that industrial-grade tool products meet standards for ruggedness while at the same time providing less weight and size to enhance user experience.

That's especially important since people have grown accustomed to ease of use when operating consumer products. They now bring that same expectation for friendly product use when they go to work. To meet both industrial grade standards and ease-of-use expectations requires technical innovation on the part of the manufacturer.

Our Sturdy and User Friendly Ring Scanner

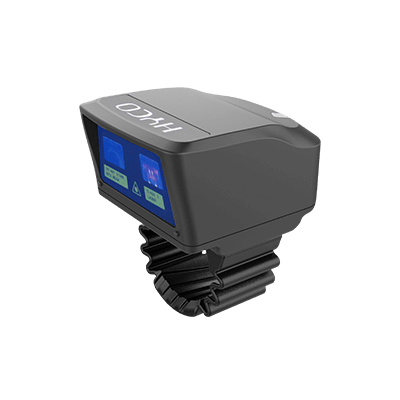

Here at HYCO we've made it our mission to be the leader in technical innovation for industrial grade products. The HYCO Ring Scanner we've developed for use in logistics and warehousing applications combines industrial grade ruggedness with ease of use.

Through revolutionary innovations, the HYCO ring scanner reduces power consumption by 95 percent and uses a single system on chip (SoC) design. Because this allows for a smaller printed circuit board, the battery size required for the typical operating time can be much smaller.

Our Hyco W26 ring scanner, fully charged, can operate for 24.5 hours (about 14397 scans). Compared to similar products on the market, our scanner provides industrial ruggedness while offering a lighter weight and smaller size to improve the user experience.

For more details:

* W26 Laser Ring Scanner

* W27 CCD Ring Scanner

* W28 2D Ring Scanner