Does Your Wearable Device Maker Meet These Universal Standards?

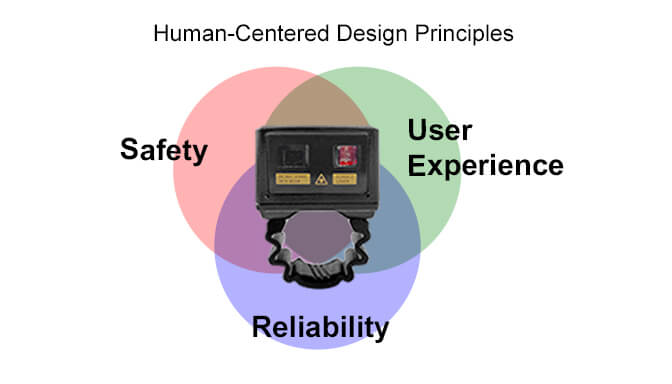

When it comes to developing wearable devices for people, companies fail at that mission if they don’t adhere to the principle of “human-centered” product design. That fundamental principle should inform all wearable design work rather than basing product development around the attainment of proprietary technology or economizing on resources and materials.

In developing any wearable device, what should be first and foremost in the minds of the product makers is user safety, followed by user experience and reliability. Those three criteria need to be applied across all product forms and taken into account for all use-case scenarios.

Safety — The Number One Priority

Wearable products must not pose any safety risk to the user. Common concerns include: Could the way the device is worn get caught or pulled into machinery? Could it get snagged by objects and compromise user safety? Could the device cause any harm with excessive movement?

It’s also critical that wearable products not overheat because of high power consumption. That’s especially the case where any parts of the device might come in contact with sensitive areas of the body, such as the head, fingers, or wrists. In addition, wearable devices must emit low levels of radiation to avoid chronic health effects, especially if the product might be used around children and pregnant women.

Comfort Is Crucial

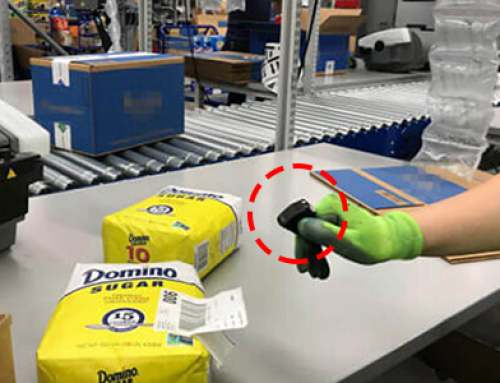

When it comes to devices that are worn for several hours at a time, weight is a critical factor in comfort. Ring-type wearables(HYCO Ring Scanner), for example, should not exceed 20 grams, and ideally remain under 16 grams. Watches(W563 Wearable Computer) should be under 250 grams, and ideally under 100 grams. Glasses weighing more than 50 grams are difficult to wear for more than 30 minutes.

Low-power consumption and the absence of heat are also basic requirements for any wearable device. Any product coming in contact with the body should not exceed the body temperature. It should also be made from sweat-proof materials that do not cause skin irritations. In short, the product should be durable while at the same time being comfortable.

The User Experience Must Be Excellent

Any wearable device has to be designed for ease of use so workers won’t balk at using it. Since users are turned off by having to frequently charge devices, the wearable must have ultra-low power consumption as that facilitates long-term continuous use. Devices must also have the ability to operate in extreme temperatures while still being robust, For example: HYCO ring scanner.

Needless to say, the device should invite operation. It should be extremely simple to use, ideally taking no more than 5 minutes to learn. As mentioned earlier, comfort in wear is also vital to gaining user acceptance.

Additional Technical Criteria

Any wearable device should meet the electrostatic discharge (ESD) standards. Statistical data suggests that human static electricity can reach up to 50 kilovolts (KV), while typically remaining under 30KV. With that in mind, hardware makers should design for 50KV ESD protection, and also test for functionality without failure at 30KV.

Because of the increased use of electronic devices throughout the workplace, electromagnetic compatibility (EMC) design becomes increasingly crucial for wearables. EMC considerations include ensuring device signals do not interfere with other electronic devices. Likewise, the wearable device should also be immune to interference from external electromagnetic sources.

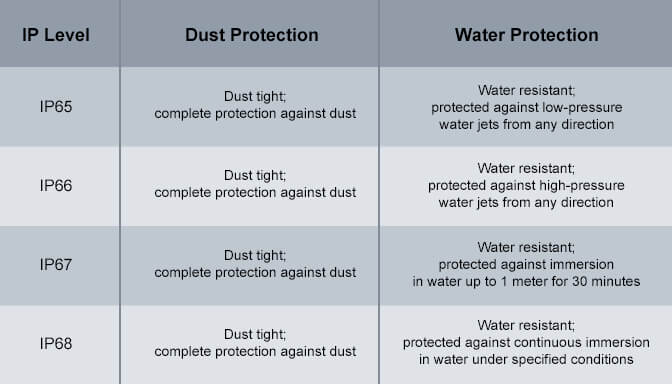

Wearables need a higher level of protection against water and dust than other devices. That’s especially true for rings and watches as they require extra protection against environmental conditions. Those devices should have a minimum recommended rating on the Ingress Protection (IP) system of 66. However, a target of IP67 rating would be optimal to ensure a wearable device can withstand exposure to rain, washing, and sweat.

Because wearables are subject to frequent movement and even accidental drops, they should withstand falls of at least 1.8 meters. Tool-type products, which are prone to more frequent drops and impact, should ideally withstand a drop of up to 3 meters(For example: HYCO ring scanner).

Wearables also have to have the ability to stay in constant communication. Communication reliability is crucial to ensure continuous operation without disconnection or crash under various wireless interference conditions. In cases of strong interference, the device should be able to quickly re-establish a wireless connection to avoid disrupting work and life.

Check That The Wearable Maker Has Met The Standards

When it comes to selecting a wearable tool for use in an industrial or warehouse environment, buyers should make sure that the manufacturer has met all the standards described above. Following these standards ensure that wearable products prioritize human needs, safety, and comfort, while ensuring both functionality and user satisfaction.