Because radio frequency identification (RFID) tags allow for the wireless transmission of information, it would seem that this technology could speed up the process of package delivery. Although the logistics and express industry have been enthusiastic about RFID for a long time, this technology still has not seen any widespread adoption.

Why is that? As a semiconductor professional with more than 30 years of experience, plus 15 years of research and development (R&D) in the logistics and express fields, I believe there are a number of reasons why RFID technology has not been able to supplant bar code labels as the most suitable mechanism for package identification.

RFID Tags Versus Bar Codes

RFID technology is a type of automatic identification technology that consists of a tag and a reader. The tag contains an antenna for wireless data transmission and a chip that encodes data. The reader communicates with the tags through radio waves.

Bar codes, on the other hand, encode information within a black-and-white pattern that must be read by a scanner. Reading the information from a bar code requires a person to swipe the bar code with a scanner. Because RFID eliminates the manual task of code scanning to obtain information, it would seem that automated wireless transmission of information would save time.

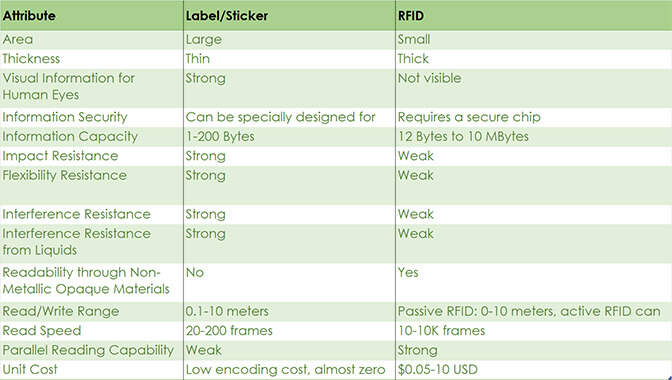

Label/Sticker vs RFID Comparison

The Costs For RFID Technology

For many years, one of the arguments against the adoption of RFID technology was its cost. Right now the cheapest RFID chip can be had for as little as $0.05 USD, with some Chinese chip companies offering even lower prices.

Although RFID tags today are somewhat more affordable, they still lag behind bar code labels in terms of information capacity. The lowest-cost RFID marker, commonly referred to as a "Tag" chip, only offers 96 bits (12 bytes) of data capacity. That amount is barely enough to describe the package’s ID number with nothing else in the way of additional information.

Moreover, special equipment is required to encode and read the chip data. If a high-capacity, encrypted RFID chip is needed to hold the required amount of information, then that increases deployment cost significantly.

RFID Benefits and Drawbacks

One advantage to RFID is that the tags can be re-used multiple times by rewriting the information stored in them. Because RFID chips are manufactured using semiconductor processes, it gives them the flexibility to have varying capacities, numerous types and models, and even integrated encryption capabilities.

Some RFID chips can also offer limited computing power. This has led to their widespread use in reusable applications such as identification cards, drivers’ licenses, public transport cards, and membership cards.

However, when RFID is used in the logistics and express industry, the technology has issues. These include the concealed nature of the data, the need for special reading/writing equipment, and susceptibility to wireless interference from metals and liquids.

When you factor in the higher costs for an RFID marker compared to linear and two-dimensional barcodes, it doesn’t make sense to use tag technology for package and goods identification. It’s no surprise then that RFID has not seen wider use in e-commerce, logistics, and express services —_ with the one exception of when dealing with high-value goods or services.

RFID Benefits and Drawbacks

Even if the costs are higher, many times a technology will be adopted if it solves a core pain point for the user. The biggest pain point for last-mile delivery drivers is quickly finding the right customer package from all the others in the crowded vehicle.

Although it would seem that RFID could help drivers quickly find a delivery package because of wireless data transmission, that’s not the case.

While an RFID tag can transmit its location to the driver, the reading range typically is a very short distance. In addition, due to the varying sizes of packages and the shifting of cargo during transit, wireless reading can’t often pinpoint the exact location of an item in the storage compartment. As a result, during a drop-off, the driver still has to get up close to an item to read the tag and confirm its the right article for delivery.

To read even larger packages, the driver even has to pick the item up and find the exact side where the RFID chip is placed in order to aim the reader. Doing that wastes more time than the driver would spend finding the package by sight.

Now if the reader's range is long distance, such as the 50-feet range claimed by some companies, the driver would only be able to confirm whether the package resides in the cargo compartment. But the extended range reading would not pinpoint the exact package location on a particular shelf. Keep in mind that when the driver enters the cargo space, all RFID tags will be read simultaneously, providing no help in locating the individual package.

Now some might argue that the RFID's signal sensitivity (RSSI) can be used to locate a package. While theoretically possible, it is neither accurate nor feasible in the confined and cluttered space of a delivery vehicle. Inside a delivery vehicle, multiple reflections off the metal walls and interference from metallic and liquid items cause multi-path transmission of radio signals. That makes it extremely difficult to determine the exact location of a particular RFID tag based on Receiving Signal Strength Indication (RSSI) when in an environment like a last-mile delivery vehicle.

RFID: No Help To Drivers Finding Packages

Although RFID technology has been used in warehousing where stored inventory is valuable or expensive, and there’s no risk of signal interference from metals or liquid, it’s not suitable for package identification in e-commerce or logistics.

While a long-range RFID reader could detect when a package unexpectedly leaves the vehicle and thus prevent theft, it offers little assistance to the driver in locating packages and may even cause more confusion. On top of that, package theft is not a major cause of loss in last-mile delivery in the United States, so adding RFID purely to prevent this issue is inappropriate.

That’s why it makes more sense to continue using bar codes for package identification. On the other hand, if the intent is to help drivers find packages more readily in a vehicle to expedite delivery, then the addition of wireless light tag on the items would provide visual and sound clues for spotting location, resulting in a more effective approach for quick retrieval.